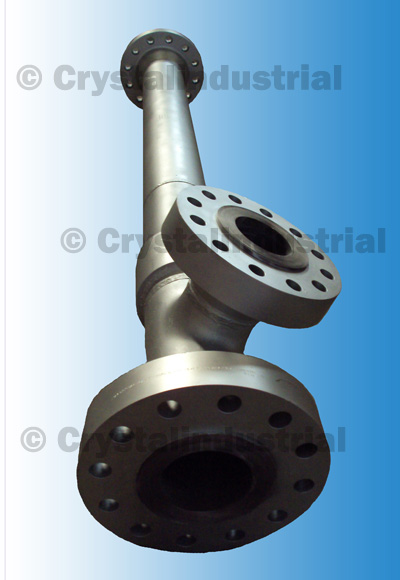

Nickel Plating Projects

Some Nickel Plating projects we have done for clients

Abrasion/Wear Resistance

Solderability

Substrate Materials

Custom-built Nickel Plating from India

Electroless nickel plating requires no anodes, power supply or any sort of electrical association. The nickel plating procedure essentially includes combining a couple of arrangements, warming them to simply close breaking point, and after that submerging the item to be plated. An auto synergist electrochemical response results and the nickel is equally kept everywhere throughout the substrate being plated.

The thickness of the nickel plating relies upon the term of inundation. To stop the nickel plating plating procedure, basically expel the article from the arrangement.

Like with all plating techniques, the shine of the nickel plating relies on upon the brilliance of the part before nickel plating. The brighter the introductory sparkle, the brighter will be the sparkle in the wake of nickel plating. By changing the surface arrangement, a mixed bag of varieties of the last complete can be accomplished.

Electroless nickel plating has numerous applications in industry. Since the framework plates equitably over all regions of the part, even down tubes and cavities, it is additionally used to plate guns, little hand devices and air cooling balances on numerous motor squares.

Electroless nickel plating happens at an inexact rate of 1 mil (1/1000") every hour. Indoor improving articles require pretty nearly 0.25 mil or 15 mins of plating. General outside things (like hand apparatuses and hand weapons) ought to get 0.5 mils or 30 mins. For things that oblige high consumption safety 1 mils or 60 mins of plating is required.

With more than 20 years' of gaining practical experience in the electroless nickel plating procedure, Crystal has added to a far reaching assortment of metal completing methodologies and methods.

This empower us to process an extensive variety of materials for our customers. For example, all ferrous substrates, including plating stainless steel, copper and its composites and aluminum amalgam.

We have made substantial technical investments in plating tanks and equipment at our Indian plating plant. This combined with engineers who bring solid experience from diverse industries, allows Crystal Industrial to offer unrivalled quality and cost savings to our clients for all kinds of electroless nickel plating solutions.

We can provide a quote based on drawings emailed to us.

Why choose Crystal for your electroless nickel plating needs?

-Deep technical and operational experience in the electroless nickel plating process, backed by many years of experience.

-A varied and diverse variety of plating systems to meet any kind of requirement for any industry. Including the option of heat treatment and shot/girt blasting.

-Support for special-purpose applications in the conncetor and electronic industries. Example : tip and copper plating.

-Experience in US and Europe. We have undertaken nickel plating for customers throughout UK, Europe and USA.

-Top-notch technical expertise, completion and quality control because of our extensive expertise in diffused nickel plating technology.

Our Services

We offer the following services for our nickel plating

World-class nickel plating

We make custom-manufactured nickel plating to meet unique requirements of your processes.

Learn MoreExtensively documented

Crystal's nickel plating offer extensive documentation and process information.

Learn MoreCommon Questions about nickel plating

Check out the frequently asked questions about nickel plating answered here.

Learn MoreGlobal Support for nickel plating

Crystal's team of engineers offer global support for our nickel plating, anywhere in the world.

Learn More